This positioner is kind of servo control mechanism for air operated automatic control system.

Typical usage and features, can be used as a double acting positioner as well as a single acting positioner because this model has a double acting pilot valve.

Dynamic characteristic are far better than any other positioner as a large capacity pilot valve is employed in the nozzle flapper circuit.

Application covers direct operation and reverse operation of both actuator and positioner pilot.

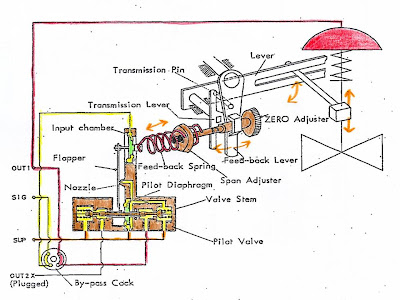

The operation of single acting positioner as picture above, the signal pressure from controller enters the input chamber and exerts a force on diaphragms. Difference of the pressurized area of the two diaphragms creates a force to push the flapper.

As the clearance between the flapper and the nozzle increase, back pressure in the nozzle decrease and the supply pressure actuated pilot diaphragms shift the pilot stem rightward to open the pilot valve.

Outlet pressure passed through the pilot valve and the bypass cock enters the diaphragm motor to operate the valve stem. The movement of the valve stem is converted into rotary movement by the effect of the lever, and further transmitted to the feedback lever through the transmission lever and pin.

Movement of the feedback lever varies the force of the feedback spring. The valve stem moves on until the spring force balance with the force of the input chamber. Consequently the valve stem is always controlled precisely in proportion to the signal pressure.

Stroke Adjusment

Stroke kan be adjusted by changing the effective number of turns of the feed-back pring. The span adjuster is for this adjustment. For shorter stroke, decrease the number of effective turn.

Zero Adjusment

Turn zero adjuster to vary the tensile strength of the feedback spring.

Sensitive Adjustment

Use zero adjuster to adjust hunting control system and the sensitivity of positioner. However the sensitivity is preset before shipment from plant and re-adjustment is not necessary unless it is not good enough on your actuator.

Another type of positioner is such a positioner that is added the feedback controlling mechanism to type standard pneumatic type positioner.

This type of positioner has been so design as to provide the regulating function of fully pressurizing (DA valve) or completely discharging (RA valve) supply air to/from the actuator separately from ordinary zero adjustment and span adjustment of various control valve and control supply and exhaust air of the positioner against full-close signal to the control valve so that the full close operation can be performed surely and easily.

DA working principle:

1. By raising the input signal pressure gradually from 0.2kg/cm^2 the air is supplied to diaphragm and the valve move downward.

2. The transfer arm moves in the direction of clockwise through the feedback lever.

3. The transfer lever moves in direction of counter-clockwise pressing the transfer pin.

4. The tension shaft of feedback spring moves to the right,

5. The tension of feedback spring strengthens and balance with input signal pressure.

6. At the time of certain valve opening (for instance, the opening of several 1%), if the tip of transfer lever touches the adjustable stopper and restrictc the movement of (3) ~ (4), the tension of feedback spring is not strengthened, therefore the valve moves to its final position (full close position) and the air supplied in the diaphragm is pressurized up to the maximum value.

However, as the feedback lever and the transfer arm have a movable structure provided with a spring, even if the movement of the transfer arm is restricted, the feedback lever is able to move independently.

RA working principle:

1. By lowering down the input signal pressure gradually from 0.1 kg.cm^2, the pressure in the diaphragm is exhausted and the valve moves downward.

2. The transfer arm moves in the direction of clockwise through the feedback lever.

3. The transfer pin follows the transfer arm by the force of spring and the transfer lever moves in the direction of counter-clockwise.

4. The tension shaft of feedback spring weakens and balance with the input signal pressure.

5. The tension of feedback spring weakens and balances with the input signal presure.

6. At the time of certain valve opening (for instance, the opening of several 1%), if the tip of transfer lever touches the adjustable stopper and restrict the movement of (3) ~ (4), the tension of feedback spring is not weakened, thus the valve moves to its final position (full-close position) and the pressure inthe diaphragm is completely exhausted.

Adjustment.

1. The stopper is set to an extreme end of the holder beforehand so that it does not interfere the movement of the transfer lever.

2.The zero adjustment and span adjustment are so made that the valve opening becomes 0-100% (or 100%-0%) against the input signal of 0.2 kg/cm^2 - 1.0 kh/cm^2. In this case, even if the full close signal of the valve (1.0 kg/cm^2 - 0.2 kg/cm^2) is issued, the balance adjustment in which the output pressure or complete exhaust is not necessary. The positioner is operating properly if the valve opening is 0% against full close signal.

3. By inputting the signal pressure corresponding to the minimum controlled opening of the positioner (usually 4-5% opening, 0.24kg/cm^2 or 0.96kg/cm^2), the valve is maintained in the condition of slight opening of about 4-5%.

4. By turning the stopper, bring the stoper into contact with the tip of transfer lever.

5. After bringing the stopper into contact with the transfer lever, turn the stopper further until it reaches the postion where the output pressure begins to change ( the position where the feedback balance begins to lose) and fix the lock out.

6. By issuing the signal of valve opening 0%, confirm that the output pressure becomes the maximum supply air pressure or the condition of complete exhaust.

Usually the mounting position of type positioner to the control valve is as shown the sketch picture beside.

In the following case, however the mounting method different from the ordinary method is necessary because the direction of rotation of the feedback lever racing mechanism must be set properly.

Reverse plunger valve. the valve is fully closed when the input increase.

The characteristic of valve opening.

From SMC and ABB control valve

Hurrah! Finally I got a weblog from where I know how to genuinely get valuable information concerning my

ReplyDeletestudy and knowledge.

Review my web-site Svetol

I am really delighted to read this weblog posts which includes lots of valuable

ReplyDeletedata, thanks for providing these statistics.

my web site - Buy Targeted Facebook Likes

Oh my goodness! Amazing article dude! Thank you so much, However I am encountering problems with

ReplyDeleteyour RSS. I don't understand the reason why I can't join it.

Is there anybody else having the same RSS problems?

Anybody who knows the solution will you kindly respond?

Thanks!!

My web site: Authentic Sidney Crosby Jersey

Ridiculous story there. What occurred after? Take care!

ReplyDeleteMy website 38000ft.com

Whoa! This blog looks exactly like my old one! It's on a totally different subject but it has pretty much the same page layout and design. Superb choice of colors!

ReplyDeleteFeel free to surf to my blog post :: Nike Blazers for Men

What's up to every body, it's my first go to see of this

ReplyDeletewebpage; this weblog consists of awesome and genuinely fine material designed for readers.

Also visit my blog post - Cheap Air Max ()

Thanks for any other excellent post. The place else may just anyone get that kind

ReplyDeleteof info in such a perfect means of writing? I've a presentation subsequent week, and I'm at the

search for such info.

Also visit my page; New Kobe Bryant Shoes

It's an awesome article in favor of all the web users; they will get benefit from it I am sure.

ReplyDeleteMy page Air Jordan

I don't even know how I ended up here, but I thought this post was great. I don't know

ReplyDeletewho you are but certainly you are going to a famous blogger if you aren't already ;) Cheers!

Also visit my page: NFL wholesale Jerseys

continue reading this l7n47w7m21 aaa replica bags replica radley bags 7a replica bags his response p1f26n7b49 replica bags philippines wholesale replica bags in pakistan fake hermes c0x99g8n87 replica bags

ReplyDeletereeeenshnengei9

ReplyDeletegolden goose outlet

supreme outlet

supreme outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet

golden goose outlet